Within the field of civil construction, the integration of advanced technologies has become an essential differential for driving efficiency and innovation in large-scale projects. In the current scenario, BIM stands out as a fundamental tool, enabling not only the creation of detailed digital models but also process automation to optimize workflow. In this post, we will explore an important and recent case study: the Red Sea International Airport Project. This emblematic project not only exemplifies the practical application of BIM methodology but also illustrates how automation in BIM projects can revolutionize the way large construction projects are planned and executed. The Case was recently published on the Dynamo blog and demonstrates how important BIM model automation is in Complex Projects and how it saves us time compared to the solutions we currently use.

About the Project

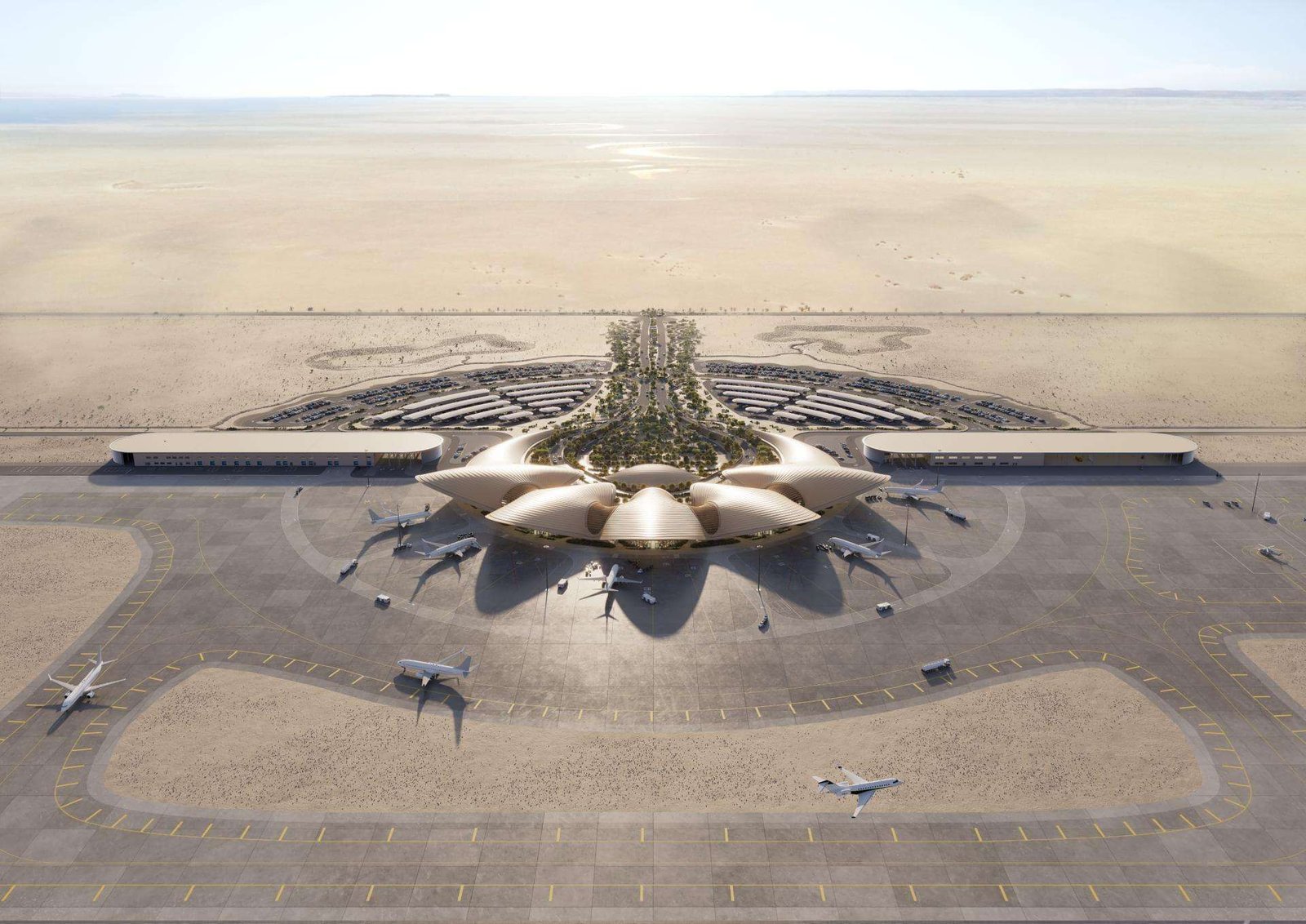

The Red Sea International Airport is being designed by Foster + Partners in collaboration with the architecture firm Jacobs as an entry point for the broader development.

Its construction began in 2021 and is located 15 kilometers from the Red Sea coast.

Its curved shape and plan are intended to mimic the desert landscape and will be characterized by five dune-shaped “pods” arranged around a central boarding and disembarkation space. Geometric complexities, from extreme double-directional curved surfaces to other engineering challenges, required the training of AI models.

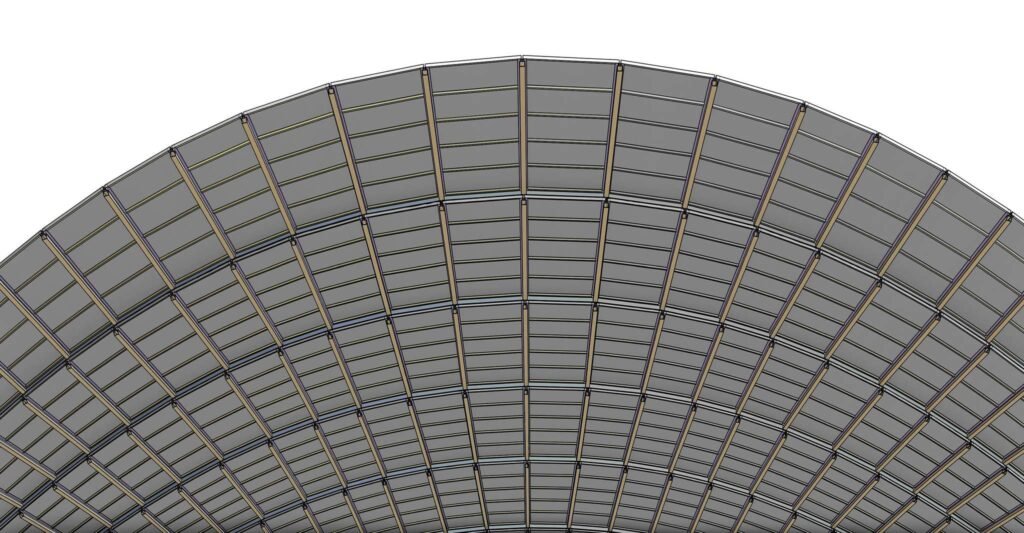

Challenge for the Red Sea International Airport Roof

The project contained over 10,000 unique curved double-directional roof panels, which, in regular scenarios, are impossible to implement manually within a very limited timeframe.

Automation Generated with Dynamo’s Help

The powerful workflow we developed in the Dynamo and Synthesize tool package allowed us to maintain a “Panel” setup using only basic coordinate and line data from Adaptive Component families—a simpler and easier-to-maintain method.

Additionally, through smart programming, an updatable system was developed that significantly reduced the need for laborious updates and maintained the integrity of project annotations and relationships.

The Synthesize tool is publicly available for community use, created and maintained by Karam Baki.

Workflow in Practice

A set of surfaces was created, one surface for each “pod,” using Fusion 360, and inserted into Revit via the [KFamilyInsert] node in Dynamo, which is the geometric node that automatically corrects and translates different data sources into native Revit geometry, thus representing the base surface of the Roof Panels.

Using Dynamo, empty Adaptive Components representing the Roof Panels were inserted as Markers, and a specialized node was used to consistently align the adaptive points.

Naming the System and Panels

A naming system was implemented to automatically assign identifiers [Panel_ID] to each panel, with the flexibility to rename them based on an external Excel file.

Additionally, exterior and interior Family Types were assigned to the empty Adaptive Components Markers. This system was crucial in managing the geometry of exterior and interior panels, with the latter featuring additional U-Channels for structural support.

Code-Driven Generation

A code was introduced capable of reading profile families from the company’s web server, obtaining their lines and coordinate systems, and mapping them onto the adaptive components markers, generating all parts of the panel.

We then batch utilized this code to produce a wide range of panels across multiple Revit instances simultaneously.

As per the illustrations above, we tricked Revit by utilizing all of the available CPU cores in a machine by splitting the CPU core utilization dynamically. This process was not only efficient but also scalable, generating 1,000 panels in just 15 minutes per instance.

Output and Integration

The generated .SAT files were handled in another code that mapped subcategories, material colorization, and separation by custom instructions. Concurrently, .CSV files containing panel data were produced, ensuring that all quantity-related information was captured and ready for integration.

Workflow in Action

Below is a comparison between Multiple Instances and Single Instance workflows, as presented in the Case Study.

Multiple (10 Instance) workflow time: 15-20 minutes.

Multiple (4 Instance) workflow time: 1 hour and 30 minutes.

Single (1 Instance) workflow time: 5-6 hours.

Updatability: Breaking the Time Barrier

The innovative approach taken with the Red Sea International Airport project shattered the constraints of time-consuming updates. By providing the ability to regenerate and reuse .SAT and .CSV files automatically, we were able to overwrite existing panels with updated details quickly and efficiently, maintaining project continuity without the need for recreating and placing panel families from scratch.

Conclusion

The Red Sea International Airport project established a new standard of efficiency and adaptability in BIM workflows. The strategic use of adaptive components as markers, combined with the power of Dynamo coding, resulted in a workflow that is both precise and flexible, with precision reaching down to 2mm clash-free results for a complex double-directional curved geometry.

Below, I leave to the blog readers the post about the Case published on the official Dynamo website by author Karam Baki, CEO and Research and Development Leader / BIM Manager of AEC GROUP in Dubai, on February 9, 2024. The original post also includes a video presenting the Project, which is also of great help in understanding the Case.

Link: https://dynamobim.org/the-red-sea-international-airport/

Deixe um comentário