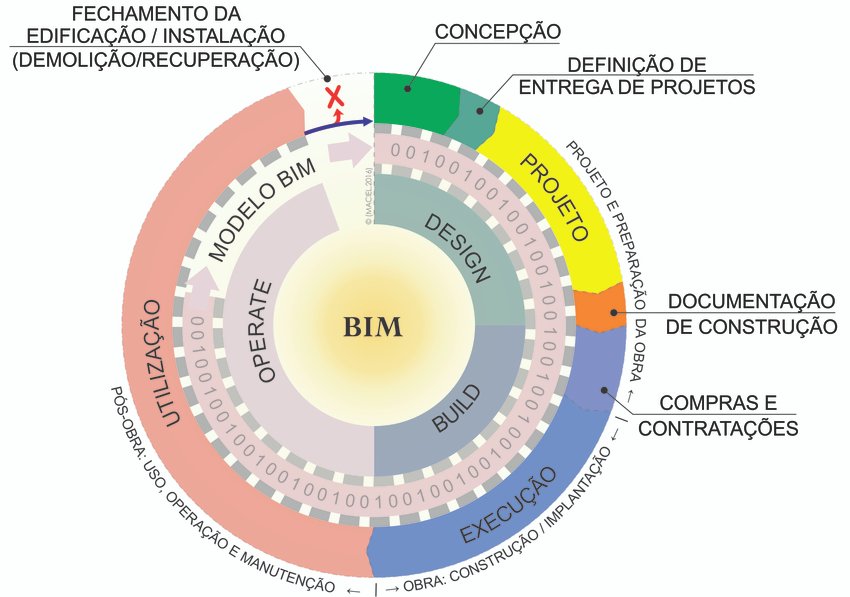

One of the most exciting facets of the BIM methodology is automation, which permeates various phases of the project lifecycle. From initial conception to construction and maintenance phases, automation is becoming a powerful ally, offering efficiency, precision, and time savings. In this article, we’ll explore how automation is transforming different stages of the BIM project lifecycle, propelling the construction industry to new heights of innovation and excellence.

What are the Phases of the Project Life Cycle in BIM?

As we’ve seen in another article dedicated to the Phases of the Project Life Cycle in BIM, let’s recall that it consists of several phases, each with its own characteristics and specific activities. Here are the most common phases:

Conception and Planning: In this initial phase, stakeholders define project objectives, identify client needs, and establish performance criteria. Initial sketches and feasibility studies are developed.

Preliminary Design: Here, initial concepts are refined and developed into more detailed 3D models. Performance analyses are conducted, and initial cost and schedule estimates are made.

Detailed Design: This phase involves creating more precise and complete BIM models, with all the necessary details for construction. Structural, mechanical, electrical, and other systems analyses are performed.

Construction: During this phase, BIM models are used to generate construction documentation, coordinate different trades, conduct virtual construction simulations, and manage construction progress.

Operation and Maintenance: After construction completion, BIM models are used to assist in building operation and maintenance. This includes asset management, planning preventive maintenance, and carrying out renovations and improvements.

Deactivation/Demolition: In some cases, especially for infrastructure projects, this phase includes planning and executing the deactivation or demolition of the building or installation.

How to Optimize Each Phase Using BIM’s Automation?

Automation in the context of BIM offers a range of opportunities to optimize each phase of the project life cycle. Below, we’ll discuss some ways to leverage automation in each phase.

Conception and Planning

1. Use concept generation algorithms to quickly explore various design options.

2. Automate project feasibility analysis, including energy and environmental performance simulations.

3. Utilize artificial intelligence tools for urban data analysis and identification of ideal project locations.

4. Automate the generation of conceptual models based on client preferences and site constraints.

5. Implement machine learning algorithms to predict costs and schedules based on project characteristics and similar project histories.

Preliminary Design

1. Automatic geometry generation tools to quickly create 3D models based on design parameters.

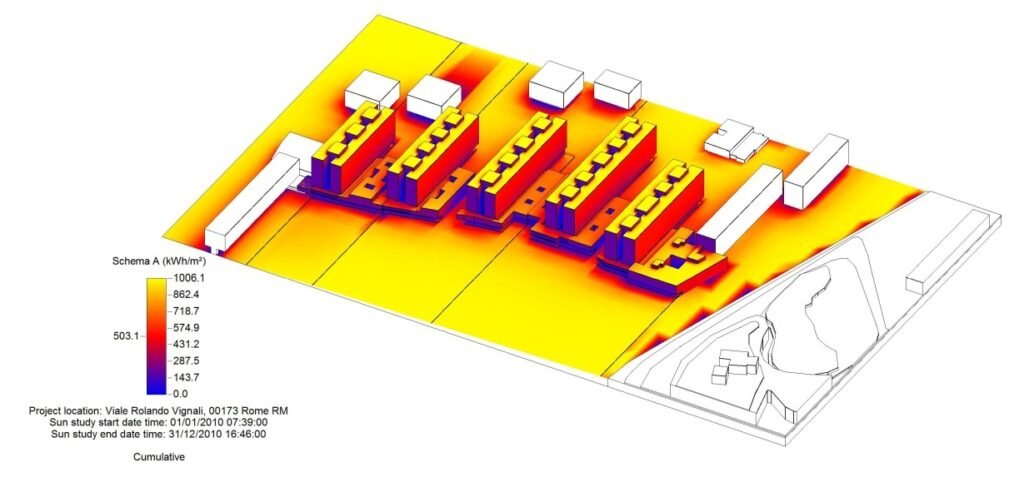

2. Integration of optimization algorithms to adjust design based on specific criteria such as energy efficiency or cost.

3. Incorporation of sunlight and shading analysis plugins to optimize building design for energy efficiency.

4. Use people flow simulation tools to optimize the layout of public spaces and commercial buildings.

5. Implementation of scripts to automate 3D model generation from topographic survey data and contextual site information.

Detailed Design

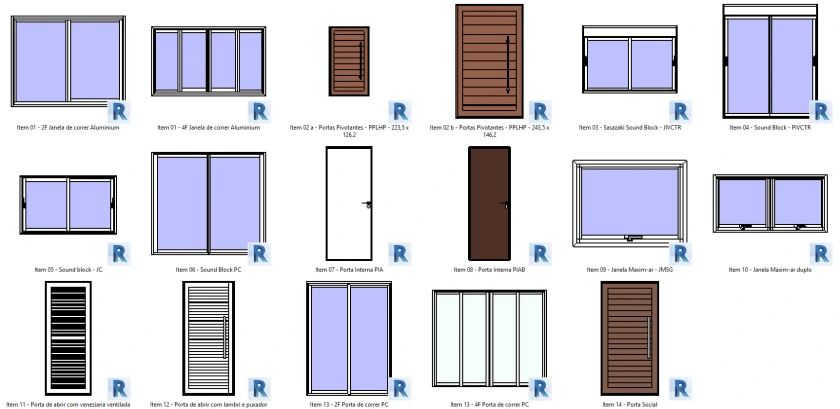

1. Use parametric BIM object libraries to accelerate model development.

2. Automation in generating construction documentation, such as technical drawings and specifications.

3. Integration of structural analysis plugins to optimize the geometry of structural elements based on loads and material constraints.

4. Utilization of parametric BIM family libraries to automate the creation of standardized components such as doors and windows.

5. Development of custom scripts to automate repetitive tasks such as placing MEP (Mechanical, Electrical, and Plumbing) equipment.

Construction

1. Implementation of BIM-based construction management systems to efficiently coordinate activities on the construction site.

2. Implementation of BIM collaboration platforms to facilitate communication and information sharing among project stakeholders.

3. Use of drones and laser scanners to automatically capture construction progress and compare it with the BIM model.

4. Utilization of augmented reality technologies to visualize the BIM model in the context of the construction site and facilitate information interpretation.

5. Development of mobile applications to collect field data and automatically update the BIM model with updated information.

Operation and Maintenance

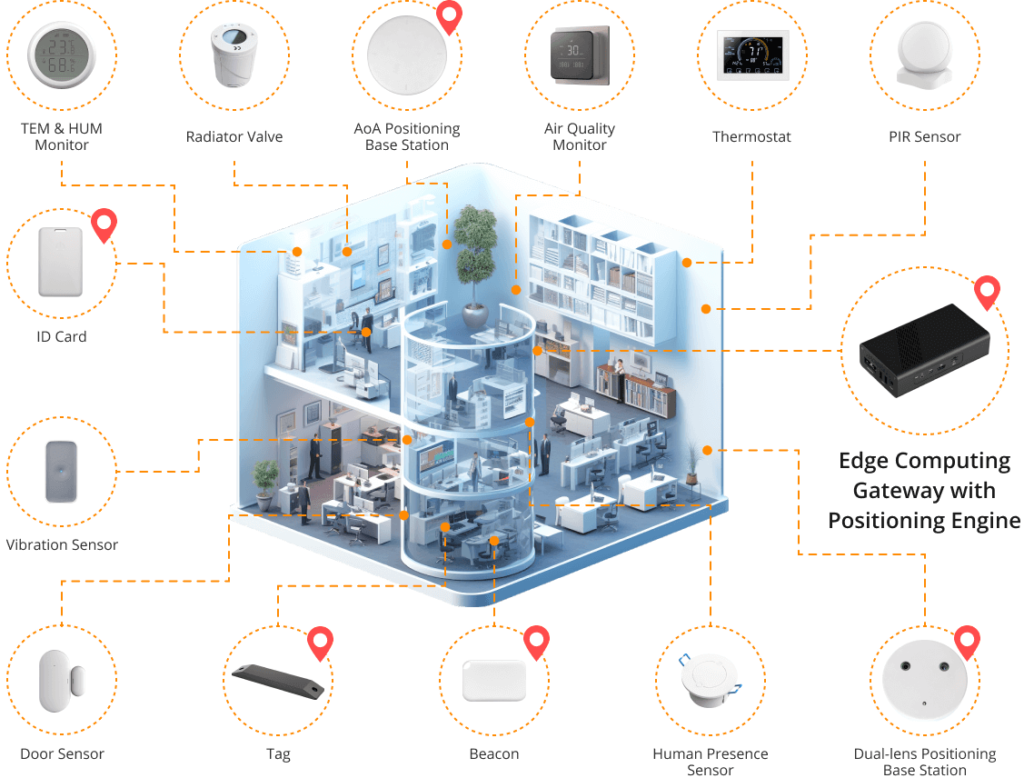

1. Integration of IoT sensors to automatically monitor building performance and identify maintenance issues.

2. Implementation of asset management systems based on BIM to track and manage all building components over time.

3. Integration of facility management systems with the BIM model to automate preventive and corrective maintenance planning.

4. Use of machine learning algorithms to identify energy consumption patterns and suggest energy efficiency measures.

5. Development of custom user interfaces to facilitate access to BIM model information by facility operators and managers.

Deactivation/Demolition

1. Use of BIM models to plan and simulate the demolition process, identifying potential risks and optimizing material recovery.

2. Implementation of demolition modeling tools to simulate the demolition process and identify potential safety risks.

3. Use of life cycle analysis algorithms to calculate the environmental impact of demolition and identify material recycling opportunities.

4. Development of geographic information systems (GIS) to track the location and final destination of materials recovered during demolition.

The Power of Automation in the BIM Project Life Cycle

In the dynamic landscape of modern construction, automation emerges as a transformative force in every phase of the BIM project life cycle. From conception to demolition, the possibilities offered by this integration of technology and construction practices are vast and of enormous potential.

By leveraging advanced algorithms, artificial intelligence, and data analytics, construction professionals are empowered to streamline processes, reduce errors, and drive innovation. Automation not only accelerates project delivery but also elevates standards of efficiency and quality across the industry.

Deixe um comentário